RING SPINNING YARN SYSTEM

Semelo sa indasteri

Hajoale, katleho ea likhoebo tsa masela e angoa haholo ke litšenyehelo tsa basebetsi, boemo ba lisebelisoa, ts'ebetso ea khoebo le lintlha tse ling, ts'ebetso ea ho phunya ke ts'ebetso ea bohlokoa ea boleng ba mabili a ohiang, a thata ho a laola, karabelo e tobileng ho tsamaiso ea eona ke data. khoele ea khaoha.Ka hona, mokhoa oa ho lemoha le ho fokotsa ho khaoha ke ntho e tlang pele ka ho fetisisa ea tsamaiso ea ho ohla.Rea tseba hore 30% ho isa ho 35% ea khefu e bakoa ke 5% ea ho khutlela morao. , ho lokisoa ke basebetsi ba makheneke le ho etsa sampole ke bahlahlobi, empa ho na le mathata a mangata.

Re ntlafalitse sistimi ea ho bona marang-rang. E ka fumana sebaka sa khefutso ea mochini ka nako le ka nepo, 'me ea ntlafatsa haholo ts'ebetso ea ts'ebetso ea liforeimi tsa ring.Khamphani ea rona e ikemiselitse ho fana ka ts'ebeletso ea ntlafatso e bohlale e tsoetseng pele bakeng sa ts'ebetso ea ho ohla ea likhoebo tsa masela, ho potlakisa. ntlafatso ea lisebelisoa tse ohlang ho ntlafatsa tlholisano ea likhoebo, le boiteko bo matla ba ho thusa basebelisi ho eketsa phaello ka ho sebelisa mekhoa e metle le e bohlale ea taolo ea tlhahiso.

Sebopeho sa sistimi

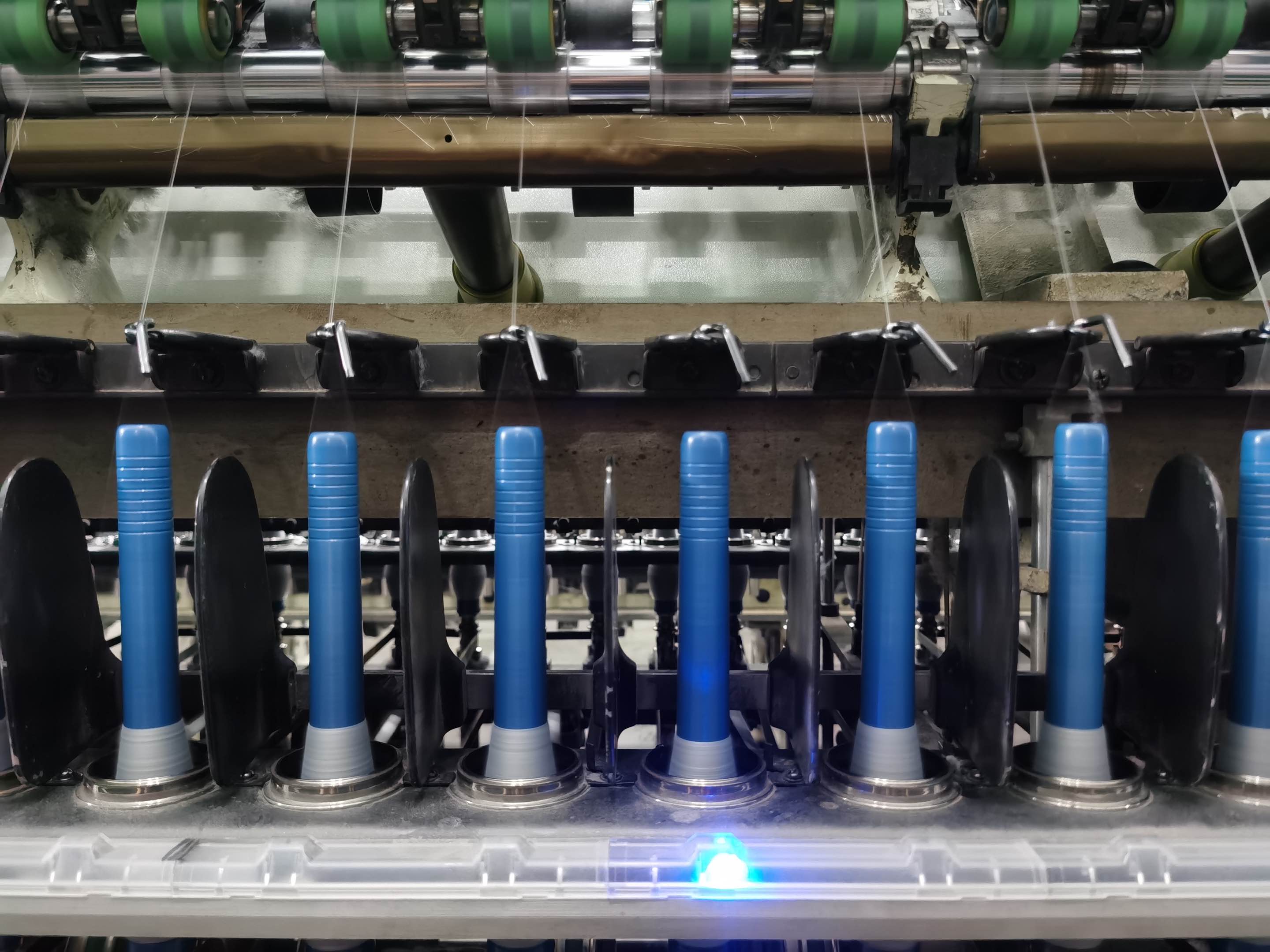

Sistimi e entsoe haholo ka lisebelisoa tsa ho beha leihlo le li-actuator.

The go baya leitlho sesebediswa akarelletsa le mong spindle go baya leitlho sesebediswa.

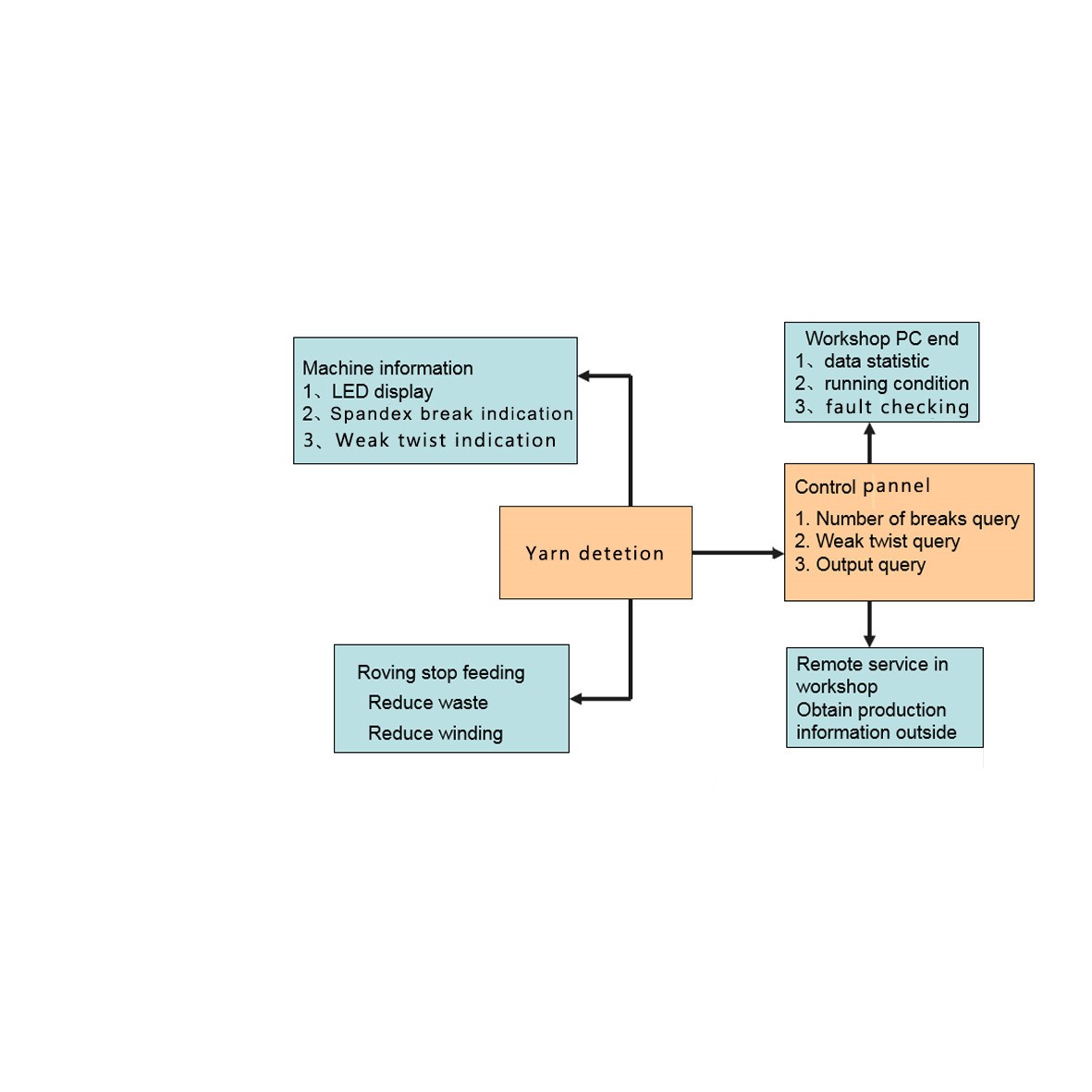

Tactuator haholo-holo e na le likarolo tse 'nè: break photoelectric sensing system,roving stop feeding device,gear end control display and end break warning indication.Sets'oants'o sa li-module tsa tsamaiso se bontšoa e le setšoantšo sa 1 ka tlase. (Har'a tsona, sethala sa tsamaiso se bohlale se ohlang leru, leihlo la tšebeliso ea matla, ho lekola tikoloho, lebone la lebone la ho robeha le ho fokola, spandex setting, suction fan speed setting, siro setting ke li-module tsa boikhethelo, ntle le li-module tsa boikhethelo joale li ke ke tsa bonts'a data e tsamaellanang. ).

Mesebetsi ea tsamaiso

Mokhoa oa ho shebella le oa ho laola o na le mesebetsi ea mochine o le mong oa mochine le pontšo, pontšo ea ho qetela ea li-gear, pontšo ea workshop, pontšo e kholo ea seva, ho fepa ka nako ea phomolo ea ho emisa, ho sibolloa ka nako ea ho robeha le boemo bo nepahetseng, ho thusa ho utloisisa lintlha tsa bohlokoa tsa boleng. ts'ebetso ea ho ohla, e fokotsa mesebetsi le tšenyo le ho ntlafatsa boleng.

E hlahelletseng ka ho khetheha ke hore tsamaiso e kentse tsamaiso ea tsamaiso ea tlhahiso bakeng sa ho ohla. E ka bokella lintlha ho tsoa ho data e ngata, ea hlahisa litlaleho tse fapaneng tsa litšoantšo le mongolo ho latela litlhoko tsa bareki, ea thusa theknoloji ea feme le basebetsi ba tsamaiso ho sekaseka, ho laola le ho etsa liqeto, le ho fana ka boiketlo ba taolo bakeng sa basebelisi.

Sistimi ea taolo ea tlhahiso haholo-holo e kenyelletsa mesebetsi e latelang:

A) E khona ho bonts'a li-spindle tse nang le likheo tsa mote, ho fumana spindle ea phoso ka nako le ho tsebisa mochini hore o lokisoe;

B) Ha ho na bukana e hlokahalang ea ho lekola palo ea khefu ea li-spindles tsa 1000 / hora le khefu ea doffing e ka shejoa inthaneteng ka nako efe kapa efe;

C) Ha ho na tlhoko ea ho kopitsa tlhahiso ea tlhahiso ea phetoho e 'ngoe le e' ngoe, sistimi e itlhahisa ka bo eona;

D) E khona ho bonts'a lebelo la spindle, qoba lebelo le tlase le ho fokotsa ho sotha ho fokolang;

E) Ka nako efe kapa efe, e ka hlahloba mefuta ea maemo a ho ohla le mochini bakeng sa kemiso ea mefuta;

F) E khona ho bona ts'ebetso le lebelo la ts'ebetso ea mechini eohle;

G) E khona ho bona kamano ea lebelo le liparamente tse ling ka nako efe kapa efe mme e ka ntlafatsa lebelo.

Likarolo tsa tsamaiso

Sistimi ea ho beha leihlo le taolo ea foreimi ea selikalikoe ke tlhahisoleseling le mekhoa e bohlale. E ka rekota lintlha tsohle mme ea etsa hore mosebetsi o bulehe le ho ba pepeneneng, ka hona e thusa tsamaiso ea sehlopha sa lithupelo, le ho fana ka motheo oa mahlale hore khoebo e etse liqeto. le ho ntlafatsa tshebetso.Sistimi e na le likarolo tse ka tlase tse hlakileng

A) Ha ho na khokahanyo ea terata pakeng tsa sensor ka 'ngoe.Ho kenya ka ho toba.

B) Sesebelisoa sa photoelectric (kapa motlakase oa makenete) se na le melemo ea ho nepahala le kutloisiso, probe e nyane, sebaka sa ho kenya pakeng tsa probe le selikalikoe se seholo, 'me ha ho na tšusumetso holim'a likhoele tsa ho phunya le ho nkela motsamai sebaka.

C) Sesebelisoa sa ho fepa sa roving stop se loketse liforomo tse tšoanang le tsa V. E amohetse khokahano ea li-modules tse feto-fetohang, ha e hloke melapo e eketsehileng ea potoloho, e tsebahatsa boemo ba spindle, ka sebopeho se bonolo le ho hlongoa habonolo le tlhokomelo. .

D) Sete e 'ngoe le e' ngoe e nang le skrini se nang le mochini oa motho, e fana ka litaelo tsa ts'ebetso e potlakileng bakeng sa basebetsi le mochini.

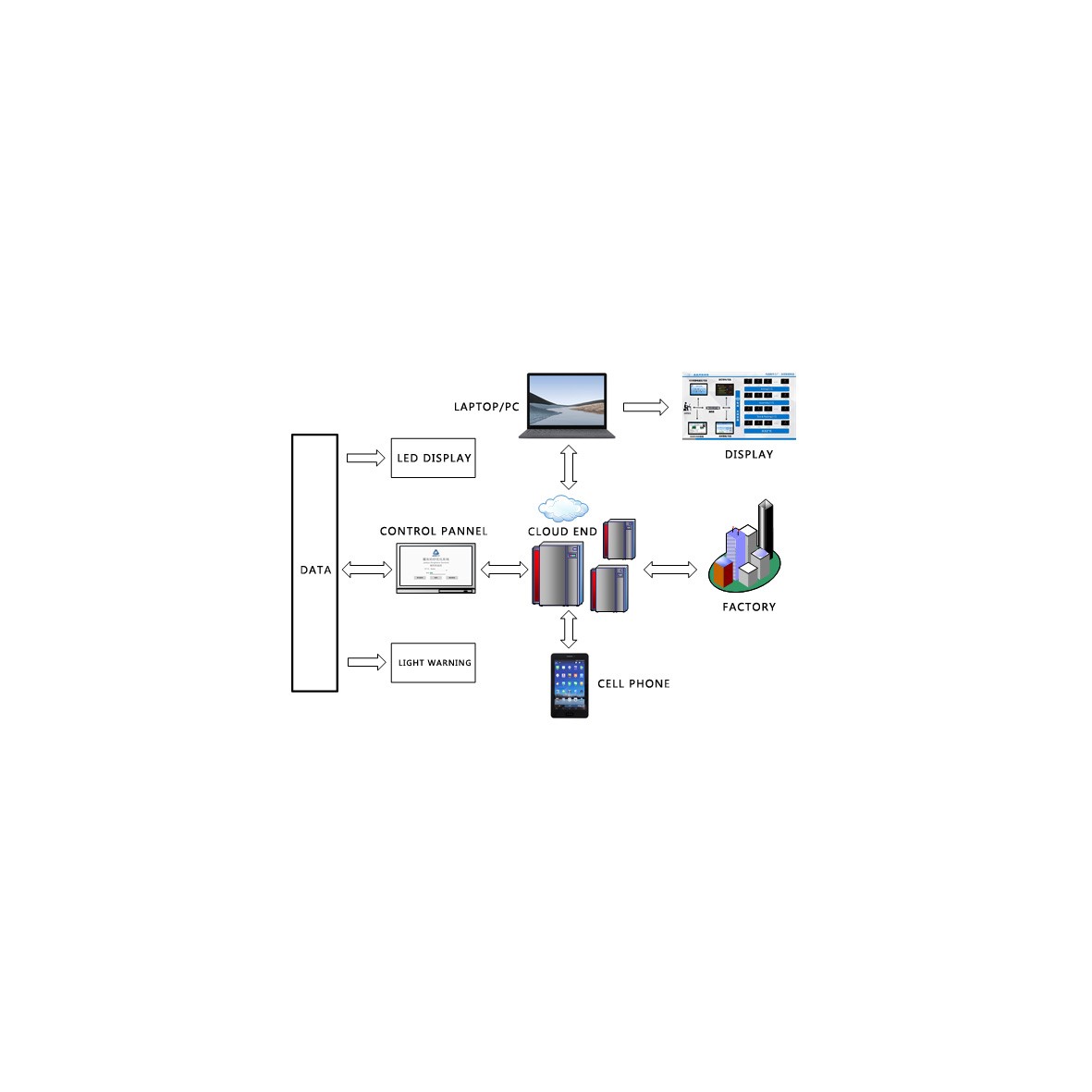

E) Moralo o nang le ts'ebetso ea wifi, bakeng sa ts'ebeletso e hole ea nako e tlang, laptop le letsoho seta khokahano e tsitsitseng ea waelese.

Meleng of break monitoring module

Mojule oa ho lemoha likheo tsa sistimi e bonts'oa haholo lebone le ponts'o. Mefuta e fapaneng ea ponts'o e emela meelelo e fapaneng.Details as below form 1.

| Boemo | Lihlopha | Tlhaloso |

| Boemo ba spindle | Leseli le leputsoa le panya | makgetlo |

| Leseli le lefubelu le panya | phoso | |

| Lebone le lefubelu le bonesitsoe | Sotha e fokolang | |

| Leseli le pherese le panya | Sensor e koahetsoe | |

| lebone | Lebone le letala le bonesitsoe | 1-4 khefu |

| Leseli le mosehla le bonesitsoe | 5-9 khefu | |

| Lebone le lefubelu le bonesitsoe | 10-24 khefu | |

| Leseli le lefubelu le panya | Likhahla tse fetang 25 | |

| Mebala e 2 e fapanyetsana panya | Ho ngola temoso / phoso ea boardboard | |

| Pontšo | Tlhaku b+nomoro | Khaola bongata |

| Lengolo E+nomoro | Bongata bo fokolang | |

| Tlhaku F+nomoro | Bongata ba phoso |

Mechini e ikamahanyang le maemo a mantlha a tekheniki

Sistimi ea ho beha leihlo e ikamahanya le maemo a tlase a foromo ea 2, li-parameter tse ling tse hlophisitsoeng ho latela litlhoko.

| Che. | Ntho | tlhaloso |

| 1 | E loketse mofuta oa khoele | 14-100s k'hothone le ho kopanya |

| 2 | Nomoro ea li-spindle | Foreimi e khutšoanyane、Foreimi e telele |

| 3 | Mofuta oa ho ngola | parallel le V ho ngola |

| 4 | Spindle gauge | 68.75MM, 70MM, 75MM |

| 5 | Diameter ea shaft cradle | 28MM, 40MM |

| 6 | Mofuta oa lesale | Sefofane, Conical |

| 7 | Nomoro ea spindle | Ho tloha qetellong ea gear (L/R) ka Taelo |

Litlhaloso tsa tekheniki ea sistimi

Sistimi e ka hlokomela tlhahlobo e bohlale ea nako ea nnete inthaneteng. Molao-motheo oa eona oa ts'ebetso le setšoantšo sa ts'ebetso li bontšoa tafoleng ea 2 le tafoleng ea 3 ka ho latellana.

Molao-motheo oa ts'ebetso ea tsamaiso ea methapo

Setšoantšo se sebetsang sa sistimi ea ho lemoha likhoele

Sistimi ea ho lekola ea foreimi e ohiang e bohlale, e na le tlhaiso-leseling ebile e bobebe. Litlhaloso tsa eona tsa mantlha tsa tekheniki li bonts'itsoe ho Lethathamo la 2 ka tlase.

| Ntho | Litaba | JADEYO Sistimi e le 'ngoe ea ho beha leihlo spindle 2.0 |

| Lisebelisoa | Ts'ebetso ea sensor | Photoelectric, Magnetic |

| Tlhaloso ea boto ea sensor | 24 li-spindles 0.7kg | |

| Mofuta oa ho qetela oa mosebelisi | Tšehetsa PC, mobile, laptop, wristbands joalo-joalo. | |

| Setopo sa ho roala | Ka nako e ts'oanang ha khefu e etsahala | |

| Taolo ea ho ngola | Bontša bophara ba rolara, lebelo la hona joale | |

| Tlhokomelo ea tlhahiso | Bontša mofuta oa khoele, sekhahla sa tlhahiso, bolelele, kotulo, linako tsa doffing joalo-joalo. | |

| Ho robehile / 1000 spindles / hora | Mocheng oa ho hlahloba lebelo la spindle le khefu ea ho qetela e etsahetse / 1000 spindles / hora | |

| Tlhahlobo ea khefu ea Doffing | Mohala, hlahloba lebelo la spindle le ho robeha ho etsahetse / 1000 / hora ea doffing ka 'ngoe | |

| Alarm ea khefutso ea ho qetela | Sensor light light wink, selaoli sa ho qetela sa gear se bonts'a boemo ba ho robeha mme ponts'o e bonts'a palo ea khefu | |

| Ho sotha hanyane | Leseli la sensor le bonesitsoeng mocheng le hlahloba lebelo la spindle, break quantity | |

| Mokhoa oa phetiso | Boto e kopanetsoeng ea potoloho e kenyelelitsoe habonolo | |

| software | Khokahano le lisebelisoa tse ling tsa ho beha leihlo | Mechini e mengata ea marang-rang e ka theha marang-rang a ho lekola le ho felisa marang-rang. |

| Tšebeliso ea tafole ea parameter | Litlaleho tse seng li ntse li le teng li ka lokisoa ho latela litlhoko, 'me hamorao li ka hlophisoa ho hlahisa le ho theha litlaleho tse ncha. | |

| Ho arolelana lintlha | Lintlha li bulehile ka botlalo, sebopeho sa data se tšehetsa Ethernet, se lumellana le sistimi ea ts'ebetso ea tlhahiso ea HMES, sistimi ea moralo oa lisebelisoa tsa ERP, sistimi ea ofisi ea OA joalo-joalo. | |

| Lintlafatso tsa ts'ebetso ea software | E ka ntlafatsoa hape 'me ea ba le ts'ebetso ea katoloso | |

| Boemo ba boleng | Li-spindles tsohle tse fumanehang marang-rang | E nepahetse ntle le litaba tse fosahetseng |

| Sekhahla sa ho hloleha ha letsatsi le letsatsi sa ho sibolla probe le tse ling likarolo tsa motlakase | Ka hare ho 1/10000, bophelo ba tšebeletso bo feta lilemo tse 10 |